Servo control systems that reduce drive-train torsional resonance are being researched at the University of Sheffield. Underpinning the research is a radically new, non-contact, low cost, high bandwidth, torque transducer based on Surface Acoustic Wave (SAW) techniques developed by Sensor Technology in Banbury, Oxfordshire and trade marked TorqSense.

Torsional resonance is a significant limiting factor to servo system performance, but to date it has proved virtually impossible to measure, model and control. The discrete rotating masses in a drive train tend to induce torsional oscillations, particularly in interconnecting shafts and most notably at start-up, and during speed or load change dynamics typical of fast acting servos. The oscillations manifest themselves in a variety of ways, for example, in work piece ‘signatures’, or chatter in machine tool cutting, drive-train noise and component fatigue.

Damping of these oscillations via feedback of shaft torque information is expected to lead to a major improvement in the dynamic performance of future servo drive systems. Additionally, the measurement can be used to enhance the bandwidth of shaft position measurement.

Damping of these oscillations via feedback of shaft torque information is expected to lead to a major improvement in the dynamic performance of future servo drive systems. Additionally, the measurement can be used to enhance the bandwidth of shaft position measurement.

Dr Nigel Schofield, who is leading the research team at the University of Sheffield, explains: “The ideal servo drive-train would be completely stiff so that the entire mechanical system reacts instantly and predictably to changes in speed, while load torque perturbations would not initiate mechanical resonance back through the drive line.

A lot of drive system designers try to achieve this by using over-sized shafts and couplings, but this is neither elegant nor efficient and is often simply impractical. In practise, the torsional resonance inherent in every drive-train reduces stability margins, forcing servo gains down and hence reducing machine performance.”

The goal of the research programme is to give machine designers servo drive trains that are ‘intelligently rigid’ and thus free from torsional losses. This will allow them to realise higher performance servo drive systems, which are more compact, yet are completely predictable and highly efficient in terms of dynamic performance.

Until recently it has not been feasible to directly measure shaft torque due to the difficulties in obtaining sufficiently reliable and accurate signals with currently available transducer technologies. In fact most torque transducers are too mechanically compliant to provide an accurate dynamic measurement of torsional excitation during speed or load changes. Additionally, attempts to derive the torque from the electromagnetic characteristics of the drive machine do not account for the various inertias of the rotating loads in the drive-train, or torque perturbations.

By using an embedded SAW based TorqSense transducer, it is possible to accurately measure and hence provide improved control of the instantaneous shaft torque from all possible sources, including machine generated torque ripple, high speed control loops and load/torque disturbances, at different points in the drive-train. The TorqSense torque measurement system is relatively small, self-contained, non-contact and is unaffected by magnetic fields. Thus it can be mounted either inside a machine or as a discrete add-on measurement device. With this additional control data, control algorithms for the servo controller can be improved.

The principle behind SAW devices used in TorqSense transducers is that they are essentially ‘frequency dependent’ strain gauges, which measure a change in SAW resonant frequency cause by an applied shaft strain. The transducer signal is transmitted via an RF couple from the rotating shaft to a fixed pick-up. By using a frequency-based concept, the signal bandwidth is increased, and electronic interference common with other analogue based technologies, for example strain gauge and inductive devices, is eliminated.

TorqSense using the SAW concept was developed, trade marked and patented by Anthony and Bryan Lonsdale, Directors of Sensor Technology, which is also working on applications for SAW technology in large machine applications. Sensor Technology’s TorqSense Transducers interface directly with a PC or PLC, eliminating the need for extra instrumentation hardware. The company has developed them to be low cost, robust and simple so that the technology is suitable for use through out a wide range of industrial applications.

TorqSense using the SAW concept was developed, trade marked and patented by Anthony and Bryan Lonsdale, Directors of Sensor Technology, which is also working on applications for SAW technology in large machine applications. Sensor Technology’s TorqSense Transducers interface directly with a PC or PLC, eliminating the need for extra instrumentation hardware. The company has developed them to be low cost, robust and simple so that the technology is suitable for use through out a wide range of industrial applications.

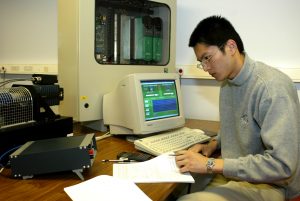

As part of an on-going evaluation of the SAW based TorqSense transducer technology, Sensor Technology have supplied seven experimentation stations incorporating TorqSense transducers to the University for use in its electrical machines teaching laboratory for first and second year undergraduate students. The transducer feeds straight to a PC running a LabVIEW™ software control platform and the students undertake a number of experiments to assess different drive control strategies. Additionally many third, fourth year and post-graduate students also use the rigs for their own thesis and project work.

“I generally reckon that equipment which can stand up to undergraduate students can take any thing that industry can throw at it”, jokes Schofield. “The results we are getting are building my confidence in SAW-based torque measurement systems by the day.”